Adapting to Climate Change: Resilient Construction Practices

India, a nation known for its diverse and captivating weather, is now grappling with the harsh realities of climate change. Unpredictable rain and cyclones have become a norm, disregarding the traditional cycles of seasons. The past decade has been one of the hottest in human history, and climate change is the reason behind these escalating challenges. Unfortunately, India's buildings and construction sector, a significant contributor to the country’s carbon footprint, accounts for about one-sixth of its total Green House Gas (GHG) emissions.

To meet today’s construction demands in a way that also embraces sustainable practices, prefabricated construction technology is being adopted across the world, and it is picking up pace in India. It is an innovative and efficient method of construction that adopts sustainable materials and processes.

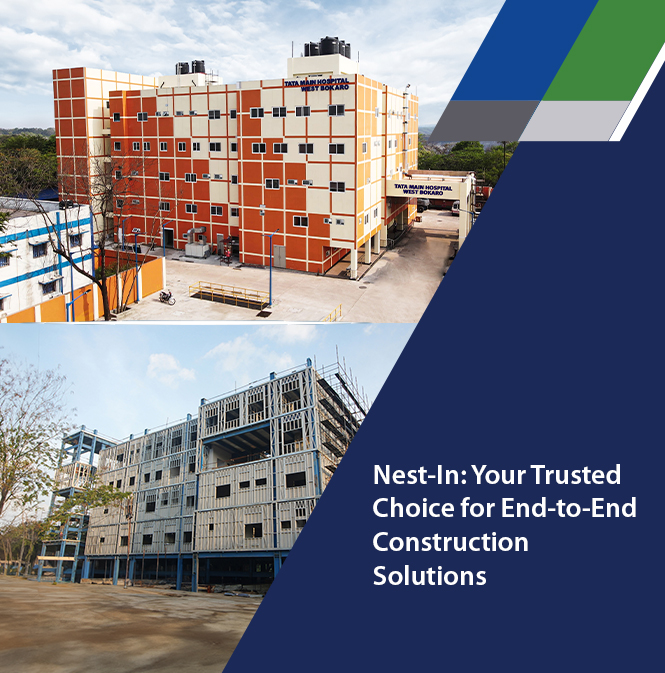

The Nest-In Solution

Nest-In from the house of Tata Steel is a leading provider of prefab construction solutions in India, and offers a wide range of prefab technology such as Light Gauge Steel Frames (LGSF), modular construction, light PEB, hybrid construction, and 3D volumetric construction.

Let’s explore how Nest-In’s prefabricated construction solutions fit into answering the challenges put forth by climate change and its consequences.

Fast Construction to Meet Immediate Needs

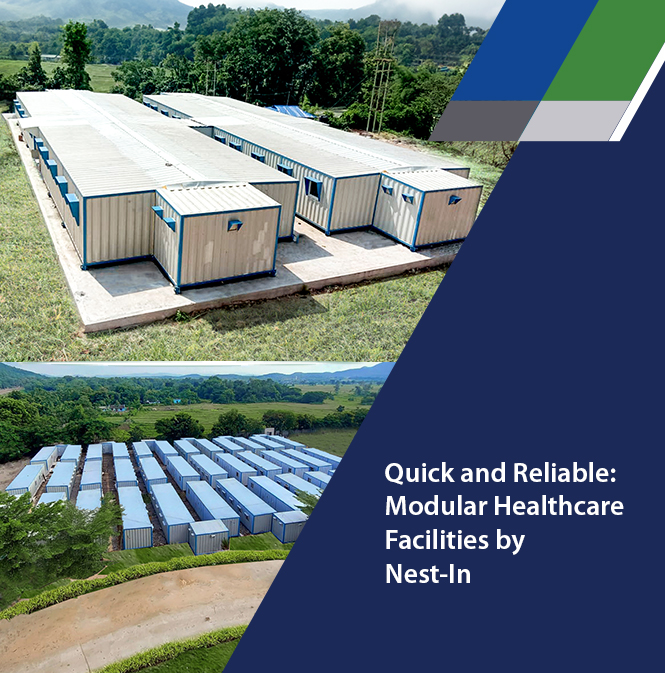

Nest-In’s prefab buildings are constructed more than 2x faster than conventional RCC buildings. This is because the prefab components and materials of the structures are built to precision in a factory-controlled environment. In case of Nest-In’s LGSF structures, the components are transported to the site only for final assembly. For Nest-In’s modular structures, the entire ready-to-use modular units are transported to the site for final installation. This leads to very less time being spent on-site, as well as minimal disruption at the construction site. Moreover, as the components of the prefab structures are made in a factory, adverse weather conditions like rain or excessive heat does not delay the construction process. Thus, in case of immediate requirements such as shelters and clinics in areas where natural disasters have struck, Nest-In’s prefab construction solutions can be deployed very quickly.

During the COVID-19 pandemic, the Nest-In team constructed a 96-bed isolation facility in Faridabad in just 3 months, and several other healthcare and sanitation facilities.

Suitable for Tough Terrains

Nest-In’s prefabricated construction solutions are much more suitable than RCC buildings for areas that are remote or in tough terrains, such as mountains. This is because:

- Nest-In’s prefab structures are built predominantly with the trust of Tata Steel, which stands sturdy and strong.

- The prefab structures don’t require very deep foundations, as they are lighter in weight than RCC structures. The foundation for an RCC building requires excavating to great depths to help the structure achieve the right stability. However, as the prefab structure is lighter, the resources and time needed for excavation are not extensive, as stability is reached at relatively lesser depth.

Nest-In has successfully constructed many structures in remote locations, such as a glamping resort in Uttarakhand, hilly cottages in Dehradun, and more.

Ability to Withstand Adverse Weather Conditions

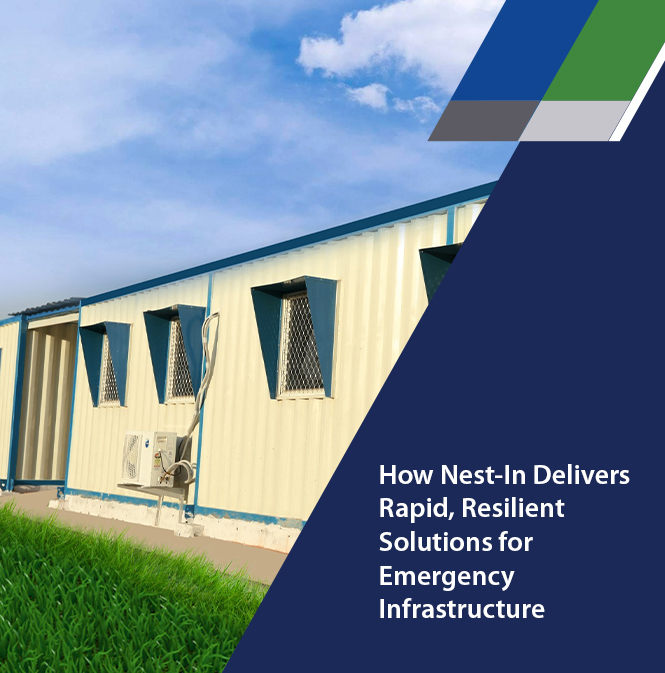

Nest-In’s strong prefab structures are able to better withstand or endure extreme weather conditions than RCC structures. This is due to the fact that they are sturdy enough to endure wind speeds up to 240km/hr, and can resist to a certain extent seismic forces of zones IV and V.

Nest-In has reconstructed 24 schools in Odisha in just 90 days, after the schools were devastated by a severe cyclonic storm. Moreover, HabiNest structures built in Chennai successfully endured the 2023 floods with little to no damage as compared to RCC buildings in the same area.

Sustainable Materials and Processes

Research shows that prefabricated constructions in India can reduce carbon emissions in the construction process by a significant 15%. Using prefabricated materials can lower a building's carbon footprint by an impressive 3.2%

Nest-In’s prefab structures are made of steel that is recyclable and reusable at the end of the product lifecycle. Additionally, during the construction process itself, 48% less fresh water is used than in RCC construction methods. This is because cement is only used in the foundation of the prefabricated building, while the rest of the construction process is dry. Thus, large volumes of water are not needed to dry and cure cement. 65% less material sources are also used, and there is overall 53% less greenhouse gas impact as compared to RCC construction processes.

In essence, Nest-In’s prefab construction processes do not overload the Earth’s natural resources with excessive usage and wastage, and seek to continually align with sustainable building practices and international goals such as the United Nations Sustainable Development Goals.

As India grapples with the impact of climate change, prefabricated construction technology is a viable solution. These practices can reduce carbon emissions and provide faster, eco-friendly, and robust structures to withstand natural disasters. Nest-in stands as a leader in this innovative space, offering fast, sturdy, and sustainable structures for disaster relief shelters, medical facilities, housing in tough terrains, and more. Know more by visiting Nest-In’s website.

Posted in MobiNest on Apr 09, 2024.

Contact Us

Recent Post

Get Better Fire and Earthquake Resistance with Nest-In’s Prefab Solutions

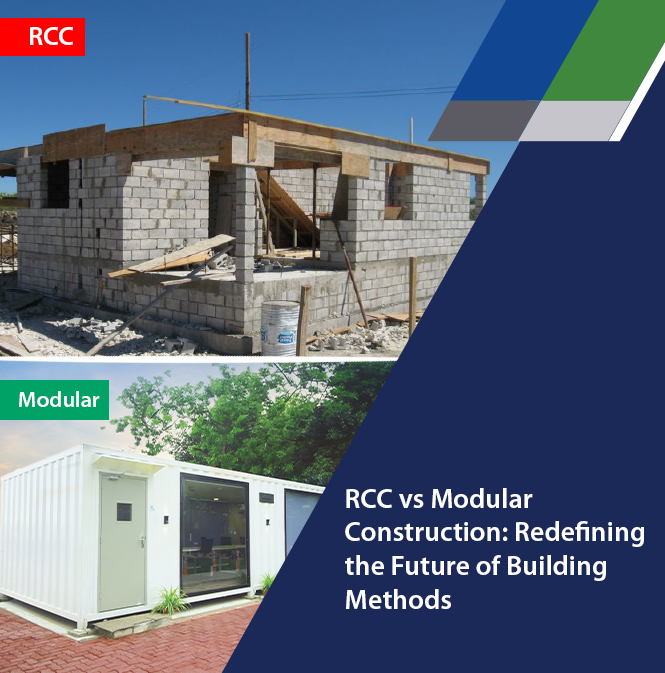

RCC vs Modular Construction: Redefining the Future of Building Methods

Top Applications of Nest-In's Modular Construction Solutions

Nest-In's Modular Construction Method Is Leading the Way

Revolutionising Hospitality: Modular Construction for Faster and Smarter Hotels

Category

- Nest-In 64

- HabiNest 58

- MobiNest 114

- Nestudio 28

- EzyNest 19

- Smart EzyNest 6

- ChargeNest 6

- Covid Offerings 4

- Brand 8

Add comment