Reasons Why LGSF Structures Last Longer

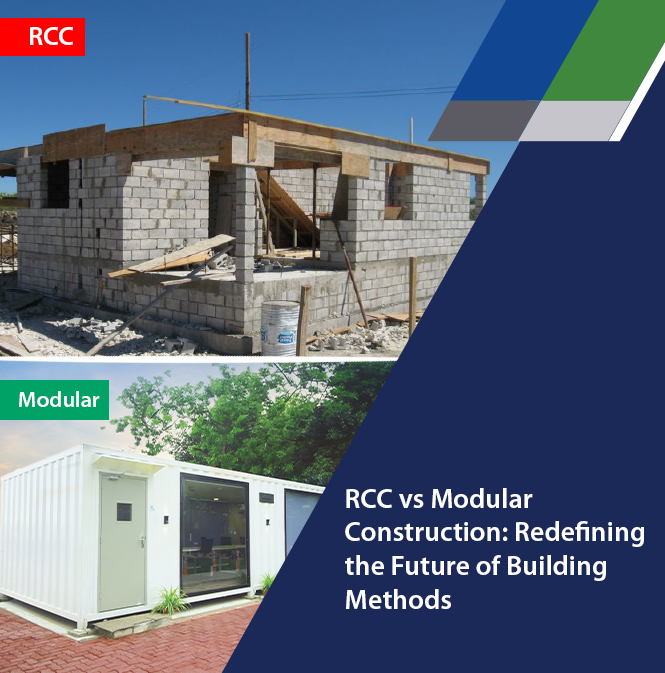

The conventional RCC construction method poses a significant threat to the environment. It is a major contributor to the fast depletion of natural resources like timber, sand, and rocks. Light Gauge Steel Frames (LGSF) are a more efficient and sustainable alternative construction solution.

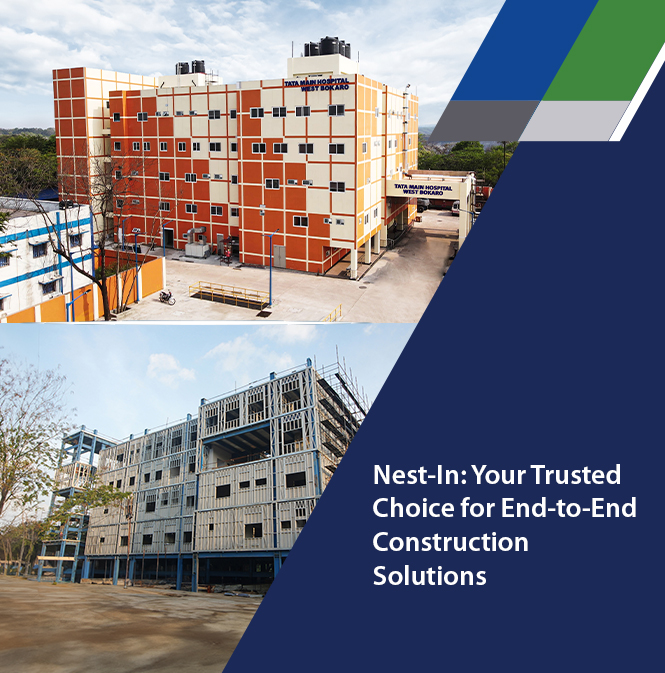

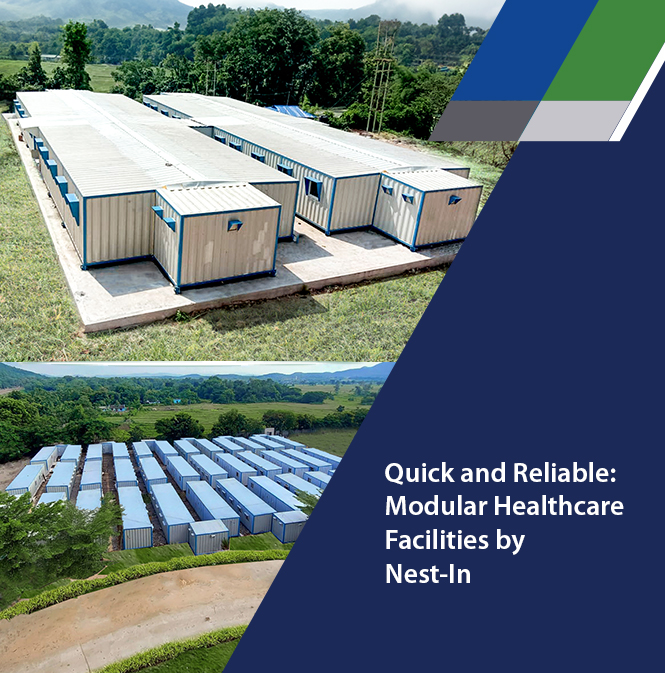

With the growing popularity of modular construction, leading prefabricated housing solution providers like Nest-In from the house of Tata Steel offer eco-friendly LGSF prefab housing solutions like HabiNest. Like all modular structures, it is manufactured in a factory under a controlled environment, enabling the completion of the project 2-3 times faster when compared to traditional brick and mortar construction.

What is LGSF?

Light Gauge Steel Frame is a one-of-a-kind construction technology that uses cold-formed steel as the primary construction material. Since steel is a naturally strong material, it is widely used to construct critical aspects of the building like roof panels, load-bearing walls, decks, and floor systems.

Another significant feature of LGSF is its versatility. It can be fabricated easily in different sizes and shapes to suit the house design. More importantly, the metal properties do not change over time, making the LGSF-based structures last long.

Let us look at why LGSF structures last longer than other buildings made with conventional construction methods.

Ability to withstand strong winds and seismic forces

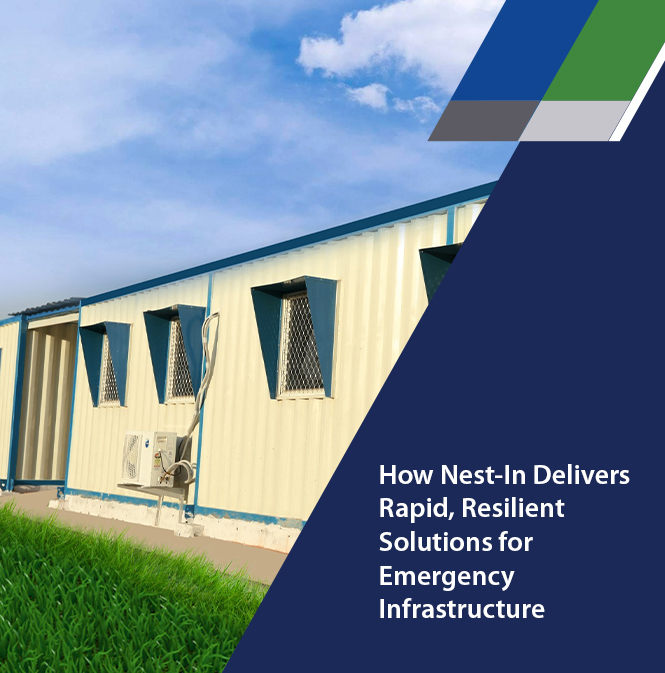

The LGSF structure like HabiNest have a superior strength-to-weight ratio, which makes them tolerant to adverse weather conditions. This structure can withstand strong wind up to 240 km per hour. As per the International Building Code, these structures remain unaffected by the seismic forces of zones IV and V, making them highly robust than conventional RCC buildings.

Fire-resistant

Steel, by nature, is a non-combustible material, making it an ideal construction material for modular buildings. Also, the fire protection for LGSF structures like HabiNest is enhanced by using gypsum-based boards for the internal lining.

Additionally, in a modular building, the use of combustible materials is much lower than in other forms of conventional construction methods. Thus, because of LGSF structures’ fire resistance power, homeowners can feel assured that their family members will remain safe during a fire accident.

Termite and insect resistant

Typically, the conventional construction methods use wood extensively for different purposes. Wood is a material that is vulnerable to termites and insects and tend to eat up the wood and make it hollow. On the other hand, LGSF structures are termite-proof as steel is not a food source for termites or any other insects, thus, increasing the durability of the structures.

LGSF – A sustainable solution

In a world where homeowners, builders and contractors aim for a sustainable solution, LGSF presents itself as the perfect solution. LGSF based modular structures like HabiNest provide environmental savings between the range of 48% to 65% when compared with RCC structures.

It requires 48% less fresh water, 65% lesser material resources than conventional structures. Also, modular constructions result in 53% lesser greenhouse gas emission than other construction methods.

You can make your dream space a reality with a modular home and add more safety and longevity by using LGSF construction technology. If you have a specific design for your home, you can contact the modular construction experts at Nest-In by Tata Steel, and they will help you with the best solution that exceeds your expectations.

Contact Us

Recent Post

Prefab Spaces Combine Strength with Modern Design

Prefab for Every Industry: Meeting the Safety and Durability Needs of Businesses

Fast, Safe, and Reliable: Prefab Is the Best Choice for High-Quality Infrastructure

Building Sustainable and Safe Infrastructure with Tata Steel Nest-In

Nest-In Prefab Construction Delivers Speed Without Compromising Quality

Category

- Nest-In 65

- HabiNest 62

- MobiNest 114

- Nestudio 28

- EzyNest 19

- Smart EzyNest 6

- ChargeNest 6

- Covid Offerings 4

- Brand 8

Add comment