Building Sustainable and Safe Infrastructure with Tata Steel Nest-In

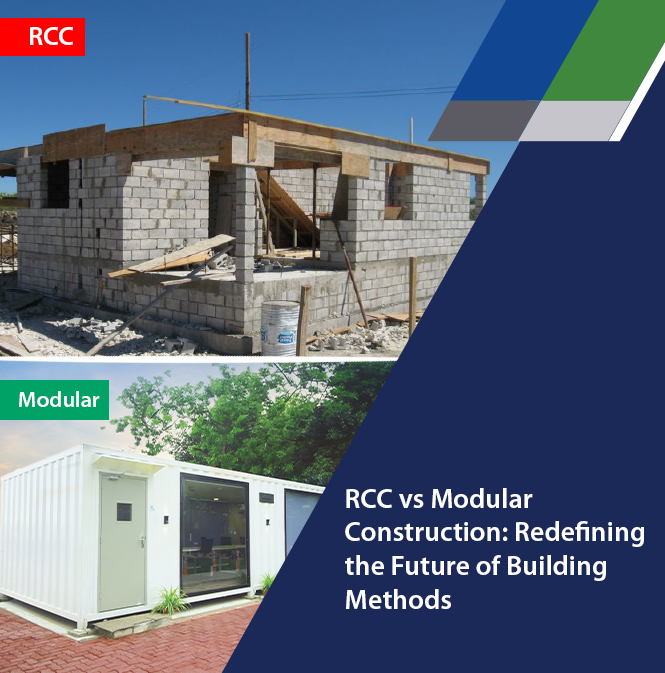

The construction industry is undergoing a transformation, as traditional building methods are posing significant challenges in the face of urgent infrastructure demands. As traditional construction processes take place on the project site, these challenges are:

- Delays due to bad weather

- Usage of large amounts of natural resources that is ultimately unsustainable

- Creation of a lot of construction waste and pollution

- Heavy dependence on the availability of a large labour force, heavy machinery, and good roadways for transport

Post-construction, ensuring structural safety while maintaining energy efficiency is a growing concern, especially for the businesses and government agencies.

So, how can we create structures that are built efficiently and sustainably, and also offer better safety and durability? The solution lies in prefabricated construction solutions by Tata Steel Nest-In.

Tackling Sustainability Challenges in Construction

Conventional construction methods are known for :

- High water consumption, needed for drying and curing cement

- Significant greenhouse gas emissions from heavy use of heavy machinery and extensive transportation required for materials

- Creating severe dust, noise, and water pollution

- Creating considerable material wastage due to manual process of manufacturing raw materials

- Extensive use of non-recyclable materials like cement, bricks, etc.

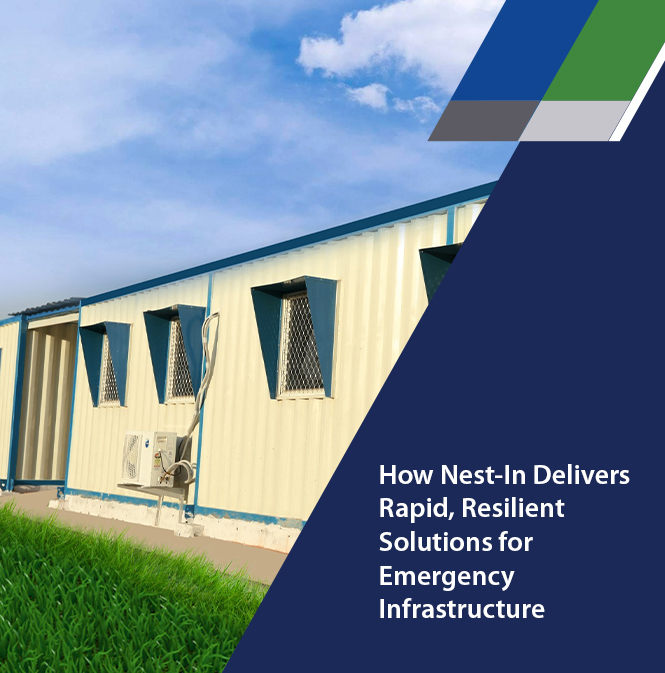

Additionally, many traditional structures face issues related to structural weaknesses and vulnerability during extreme environmental conditions like earthquakes, storms, and floods. As the demand for environmentally responsible and resilient buildings grows, adopting an alternative approach becomes imperative.

Sustainability at the Heart of Nest-In

Nest-In offers an innovative solution to these challenges. Utilising advanced prefabricated construction processes to create steel-based structures, Nest-In delivers efficient and durable prefab spaces that meet modern sustainability standards.

Compared to traditional construction methods, let’s look at the advantages of the prefab construction process:

- 48% less freshwater is used, as water is used only in the foundation and the above-ground structure is dry

- 53% less greenhouse gas impact is made. The building components are manufactured offsite and transported to the site only for final assembly/installation and connections. This greatly reduces the need for multiple transport vehicles, heavy machinery, and a large labour force

- As most of the construction takes place there is minimal onsite disturbance and pollution

- Tata steel is used as the main material in the prefab structures, which is a recyclable material

Another key aspect of Nest-In’s approach sustainability is enhanced insulation properties. Our prefabricated structures provide superior thermal insulation, which contributes to significant energy savings.

How does this happen?

Improved insulation reduces energy consumption for heating and cooling. For example, in a traditionally built space, an air conditioner or cooler would have to run for 7 to 8 hours to maintain coolness on a very hot day. Under the same conditions, the same machine would run in a prefab space for almost half the time (~4 hours) to maintain coolness.

Ensuring Safety with Prefabricated Solutions

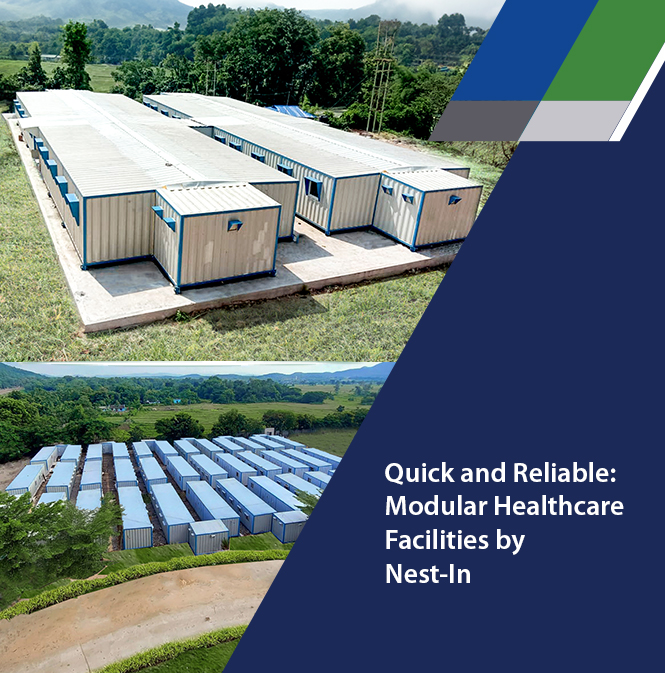

Safety is a crucial factor in construction, and Nest-In excels in delivering robust, secure, and high-quality structures. This measure of safety is two-fold:

- Firstly, the prefabricated structures themselves are engineered for superior strength. They are designed as per the environmental conditions of the project site area, and can withstand earthquakes up to Zone V, high-speed winds up to 250 kmph, and fire up to 90 minutes.

- Secondly, the construction process offsite and the assembly/installation process onsite is conducted with the stringent safety standards of Tata Steel. Our workers are skilled experts and always wear PPE both off and on the site.

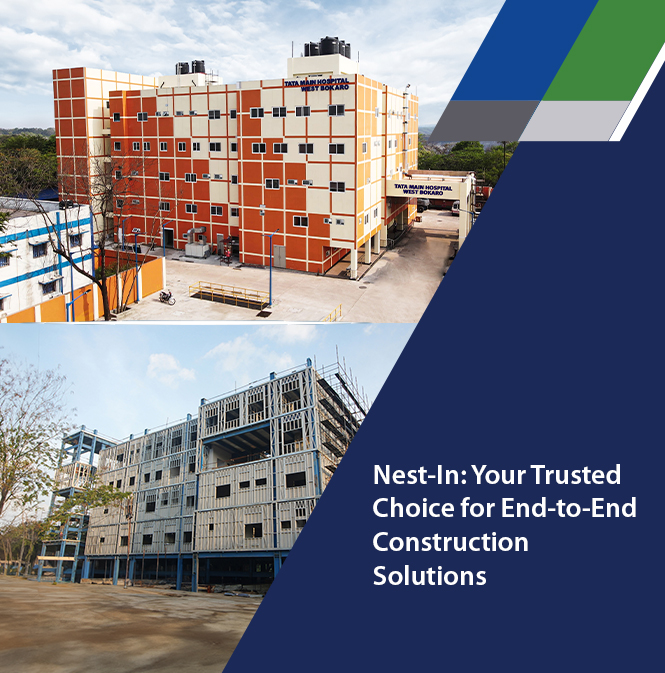

Versatile Solutions for Multiple Applications

Nest-In’s prefabricated construction solutions cater to diverse industry needs. We provide efficient, sustainable, and safe structures for multistorey offices, schools, and accommodation, large warehouses and training centres, modular meeting rooms, hospitals, clinics, and sanitation blocks, and cottages, villas, farmhouses, and home rooftop extensions.

With sustainability and safety at our core, Nest-In is redefining the future of construction. By utilising recyclable materials, reducing environmental impact, and prioritising safety, our prefab solutions are setting new industry benchmarks and providing customers with modern and durable structures.

Visit our website to explore our full range of prefabricated construction solutions.

Posted in HabiNest on Mar 07, 2025.

Contact Us

Recent Post

Prefab Spaces Combine Strength with Modern Design

Prefab for Every Industry: Meeting the Safety and Durability Needs of Businesses

Fast, Safe, and Reliable: Prefab Is the Best Choice for High-Quality Infrastructure

Building Sustainable and Safe Infrastructure with Tata Steel Nest-In

Nest-In Prefab Construction Delivers Speed Without Compromising Quality

Category

- Nest-In 65

- HabiNest 62

- MobiNest 114

- Nestudio 28

- EzyNest 19

- Smart EzyNest 6

- ChargeNest 6

- Covid Offerings 4

- Brand 8

Add comment