What is the life cycle assessment of a solution?

What Is the Life Cycle Assessment of a Solution?

Life Cycle Assessment (LCA), also called life cycle analysis, is a holistic way to measure the impact of a product, service, or process on the environment during different life stages/cycles. Different parts of the product's or process' life cycle can affect the environment in many ways.

LCA studies are guided by ISO 14040 & 44 and involve a complete list of inventory flow in each stage of the product's life cycle, including materials, energy, emission, waste generated, etc. LCA can be conducted for different scopes, which are:

- Gate to gate – Focuses only on the manufacturing process

- Cradle to gate – It focuses on the extraction of raw materials from nature until they reach the manufacturing unit.

- Cradle to grave – From the extraction of raw materials to the product disposal

Conducting a Life Cycle Assessment of a product has many benefits. It helps improve product development in efficient policymaking.

Steps of life cycle assessment

LCA is a standardised method that makes the assessment transparent and reliable, and as per the ISO standards, there are four main steps of LCA.

- Defining the goal

- Analysis of the inventory

- Assessing the impact

- Interpreting the findings/assessment

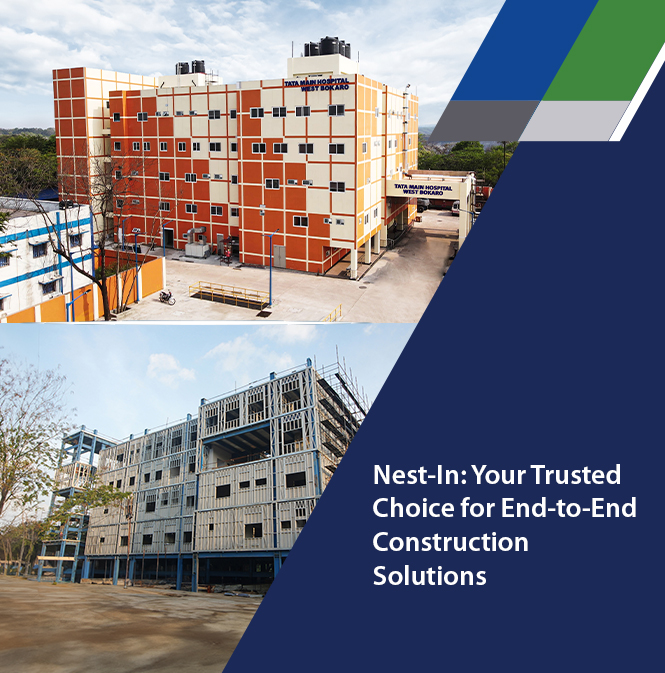

Life Cycle Assessment of HabiNest, a prefab construction solution offered by Tata Steel Nest-In

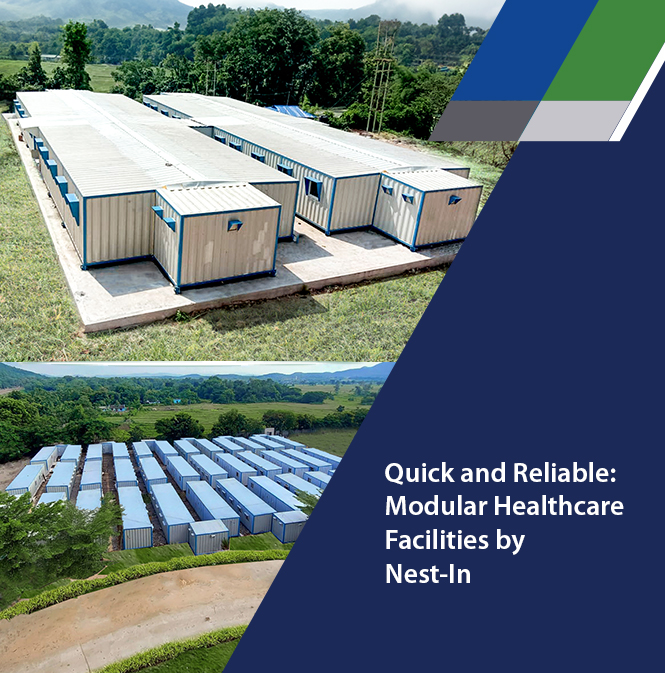

HabiNest is a Light Gauge Steel Frame (LGSF) solution ideal for building residential buildings and industrial amenities. These buildings are constructed in one-third the time it takes to build a structure of the same size using conventional methods.

Recently a LCA study was conducted on a HabiNest structure of classroom building. The total built area of the construction was approximately 2400 Sq. Ft which was compared with a conventional structure of a similar size.

The total material used in HabiNest was about 192 tons, while for a traditional structure of similar size, it was 547 tons.

Although the construction of HabiNest requires different materials, this construction method uses only 35% of the material resources compared to a conventional structure. Thus, it helps converse a significant amount of resources.

The greenhouse gas-related impacts of HabiNest are about 53% less and uses 48% less fresh water when compared to a conventional structure.

Overall, the LCA study found that the environmental impact of HabiNest is comparatively less than a conventional structure and therefore is an environmentally preferable solution.

Contact Us

Recent Post

Prefab: The Smart Choice for Durable Infrastructure

The Process of Creating High-Quality Prefab Spaces

Prefab Spaces Combine Strength with Modern Design

Prefab for Every Industry: Meeting the Safety and Durability Needs of Businesses

Fast, Safe, and Reliable: Prefab Is the Best Choice for High-Quality Infrastructure

Category

- Nest-In 66

- HabiNest 63

- MobiNest 114

- Nestudio 28

- EzyNest 19

- Smart EzyNest 6

- ChargeNest 6

- Covid Offerings 4

- Brand 8

Add comment