How Does Modular Construction Reduce Material Waste?

As it stands today, the construction industry is far from being a sustainable industry and is responsible for producing nearly 50% of the global landfill waste.

According to reports, in 2019, the construction business worldwide generated 600 million tons of waste, with more than 143 tons going straight to landfills. The kind of waste the industry produces is even more concerning. Steel, concrete, and aluminium are the most used construction materials that end up in landfills.

Producing these materials accounts for nearly 23% of greenhouse gas emissions. So, such wastage can have a severe impact on the environment. Experts suggest that if the current trend continues, then by 2023, the global construction industry will produce about 2.2 billion tons of waste.

With the rising concerns about construction-related wastage and its impact on the environment, people are looking at various solutions. One such solution is modular construction.

Let us see how modular construction helps reduce waste.

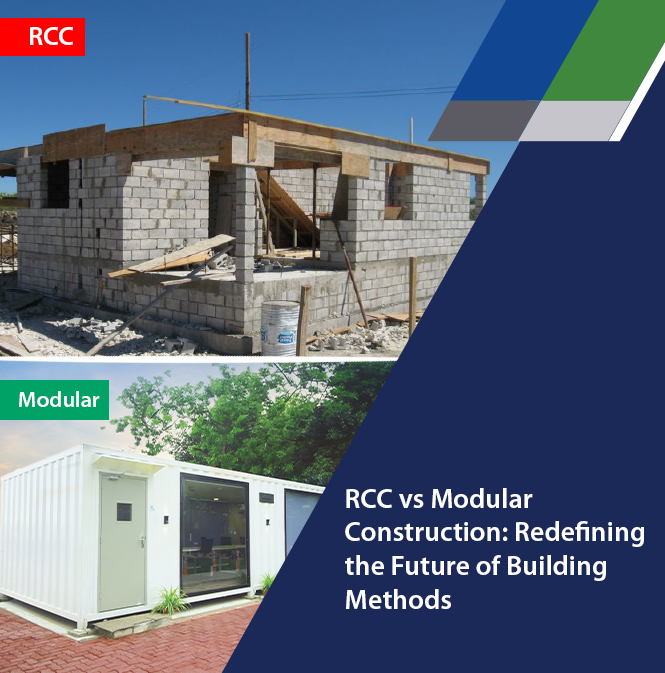

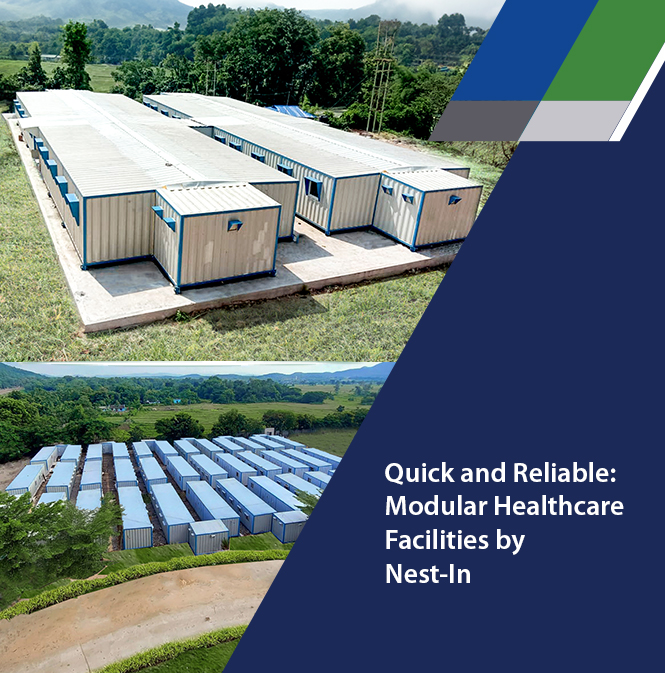

Modular construction is a unique technology wherein the different parts of a building are manufactured in an off-site location under a factory-controlled setting. Once all the modules or the building parts are manufactured, they are shipped to the site for final assembly and finishing. This technique open doors for sustainability and less construction waste.

Uses lesser materials

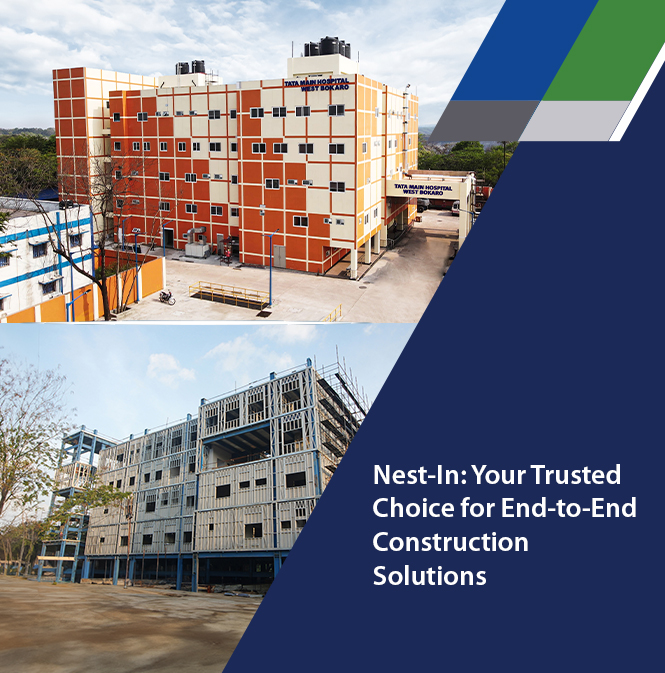

One of the most significant benefits of modular construction is that it helps reduce material usage from the start. In India, Nest-In from the house of Tata Steel, the leaders in modular construction, offers a wide range of prefabrication home solutions like HabiNest. It is a designer grade, modular home solution that provides the benefits of utility and aesthetics. A HabiNest structure consumes 48% less fresh water than a similar conventional structure over its life cycle.

Since these units are built in a factory as per specific requirements of the customers, all the aspects of the house, including walls, floor joints, roofs, interiors, etc., are detailed to the last millimetre so that the construction is done with utmost precision and reduce wastage of materials.

Such accurate construction is impossible to achieve with the traditional RCC construction. As the modular construction services work on multiple projects simultaneously, they optimise the usage of the materials across projects, thereby reducing the wastage that may otherwise end up in the landfills.

Allows easier recycling of materials

Modular construction solutions like HabiNest cuts down the weight of the structures by up to 70% than traditional brick and mortar construction. Thus, it requires less foundation, leading to lesser waste produced at the construction site.

Since the modular solutions like HabiNest are built in the same space, it is easier for the modular construction service to easily move the used or excessive material from one project to another. Since the materials are stored safely in the construction unit under a controlled environment, they are completely safe from weather-related damages, resulting in few discarded materials.

By creating less waste and focusing on recycling the building materials, modular home construction is a much greener and sustainable solution compared to the traditional RCC construction. To know more about HabiNest and other prefab solutions, you can visit the Nest-In website, and we will be happy to help.

Posted in HabiNest on Mar 30, 2022.

Contact Us

Recent Post

Smart Infrastructure Solutions by Nest-In

Modular Solutions That Save Time and Maintain Quality

A Closer Look at Nest-In's Methods: Types of Prefab Construction Technologies

Modular Construction in Prefab: A Modern Approach to Building

Category

- Nest-In 79

- HabiNest 65

- MobiNest 110

- Nestudio 28

- EzyNest 20

- Smart EzyNest 6

- ChargeNest 6

- Covid Offerings 4

- Brand 7

Add comment