How Nest-In's Prefab Technology Leads to Better Energy Savings

In the face of escalating energy demands and the accompanying rise in pollution, construction businesses now hold a crucial responsibility to prioritize conservation and embrace sustainable practices. Recent data from the International Energy Agency (IEA) indicates that the dynamic construction sector represents 36% of global energy consumption and 40% of carbon dioxide emissions. As urbanization accelerates, the potential for environmental harm grows, emphasizing the urgency for proactive measures to ensure a cleaner, sustainable future.

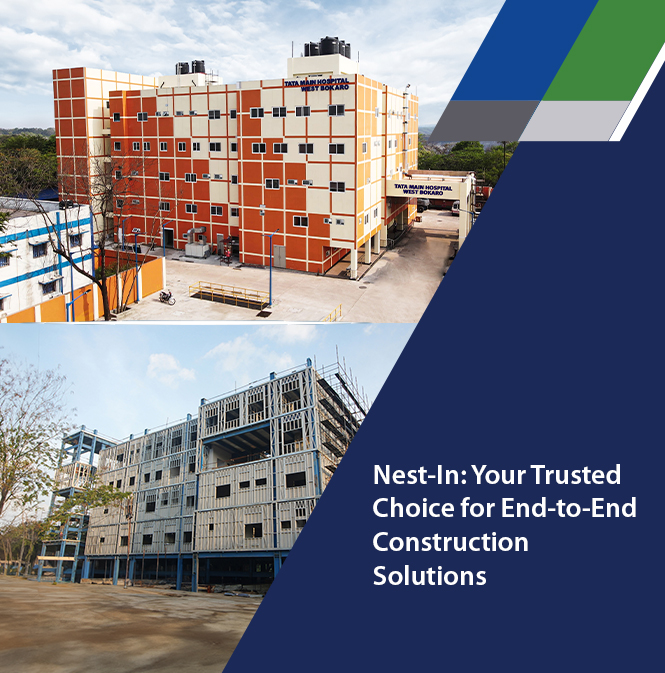

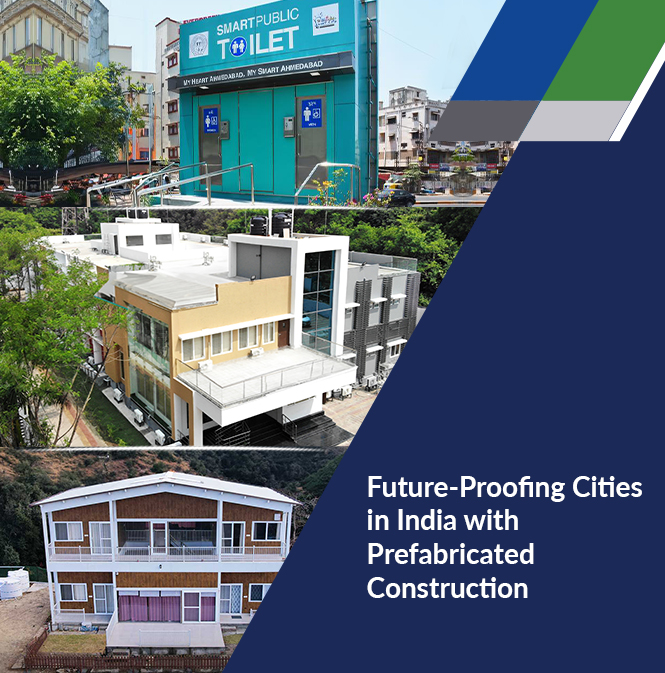

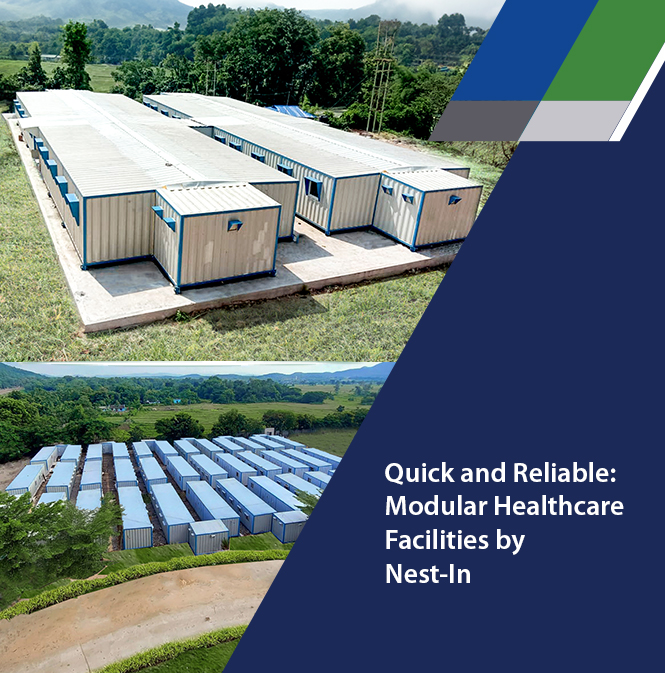

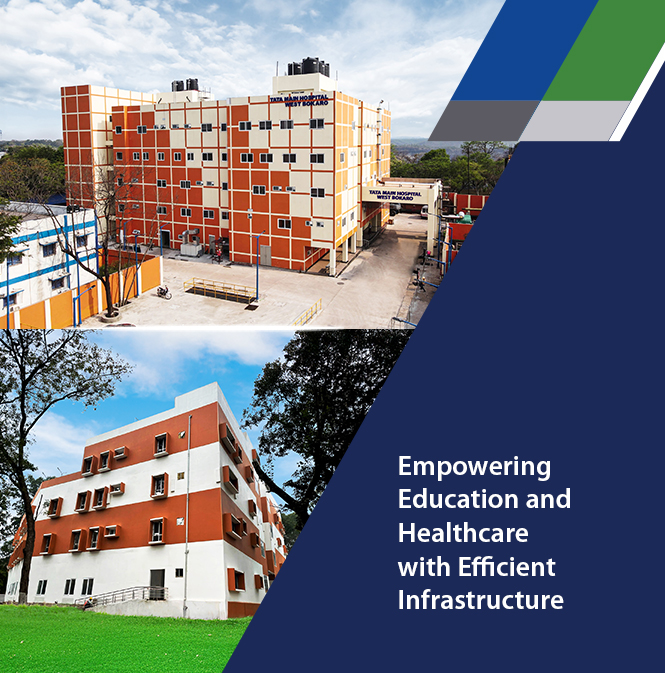

Many businesses in the construction industry are making decisions that pave the way to sustainable construction. Though many companies are working towards this concern, one prominent name is Nest-In from the house of Tata Steel. This prefabricated construction solutions company is playing an instrumental role in driving the country toward an energy-efficient future with its wide range of prefab-sustainable construction solutions.

Nest-In: Forging a Greener Path to Carbon Neutrality

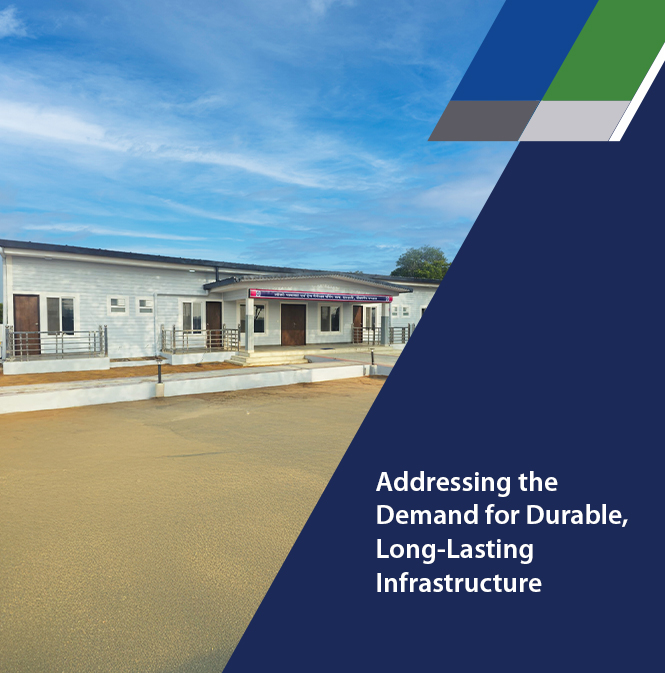

Nest-In from the house of Tata Steel offers a diverse range of. With steel-based prefabricated construction solutions a mission to provide complete turnkey solutions and a commitment to a unique customer experience, Nest-In has become a trailblazer in the realm of prefabricated constructions. Serving over 26 states and 7 Union Territories in India, Nest-In plays a pivotal role in creating a better life for millions of Indians, making its mark across industrial infrastructure, housing, sanitation, portable cabins, and lifestyle solutions.

Unveiling Energy Conservation at Every Phase of Prefabricated Construction

Prefab technology delivers energy conservation benefits from the cradle-to-grave product cycle of a building.

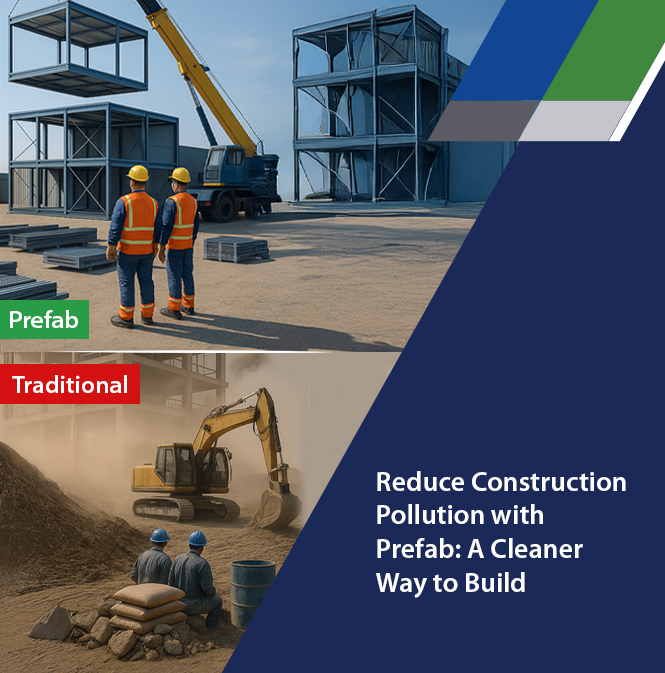

The construction phase focuses on reduced material usage, off-site fabrication, reduced construction time, and less site disruption.

Off-Site Fabrication

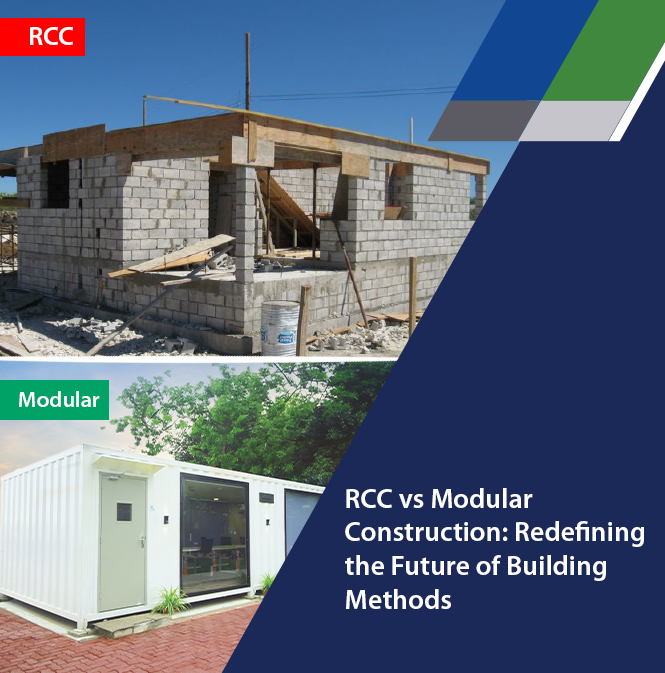

For LGSF structures, the manufacturing of components and materials is done in a factory-controlled setting. For modular buildings, the entire structure is created in the factory. For both types of prefab construction, this factory-controlled process ensures efficient and accurate production, with significantly lower energy consumption compared to traditional on-site construction methods, which employ extensive use of heavy machinery like cement mixers to make the building materials.

Reduced Material Resources

Prefabricated construction processes minimise usage of material resources, creation of waste, and demand for energy.

Foundations for prefab structures are not required to be as deep as compared to RCC structures. The above-ground prefab structure does not use traditional materials like cement, concrete, and bricks; it uses steel frames and fibre-cement, gypsum boards for ready walls. Therefore, there is no requirement for extensive use of heavy machinery like excavators, cement mixers, and earth movers. Additionally, large amounts of water are not needed to mix and cure cement. Thus, Nest-In's utilise prefab construction processes 48% lesser fresh water and 65% fewer material sources than traditional construction methods.

Reduced Construction Time

The factory-manufactured nature of the prefabricated components translates to building material that is precise and accurate, eliminating the back-and-forth on material revision. Moreover, the manufacturing process is not hampered or delayed by adverse weather conditions like rain, heat, floods, or landslides, as it takes place off-site in a controlled environment.

Additionally, for LGSF structures, the components are transported to the site only for final assembly of ready drywall boards onto fixed steel frames. For modular buildings, the entire structure is transported to the site only for final installation and electrical and plumbing connections. This leads to less energy required for extensive transportation and equipment operation, as compared to RCC construction methods.

As a result of these processes, LGSF structures are constructed 2x faster, and modular structures are constructed 3x faster, than traditional RCC buildings.

Less On-Site Disruption

Prefabrication's streamlined approach minimises the reliance on heavy machinery and intensive on-site work.

To understand how this works, let’s look at this example of constructing a prefab structure for a school. As the components for the prefab school building are manufactured off-site in a factory-controlled environment, there is no requirement of heavy machinery like cement mixers and earth movers, as well as labourers and workers on-site. Due to this, the construction process is 2x faster, there is less air and noise pollution, and less construction waste generated, as compared to on-site RCC construction.

As a result of the prefabricated construction process, the school building is constructed faster and without generating copious amounts of pollution and waste on the operational site of the school.

In the usage phase, prefabricated construction materials aid in improving thermal performance and reducing air leakages.

Improved Thermal Performance

Prefabricated structures have high-performance insulation and energy-efficient building envelopes, leading to decreased energy consumption for heating and cooling purposes.

Reduced Air Leakage

Precision in fabrication and assembly minimises air leakage, further enhancing energy efficiency during the structure's usage phase.

The end-of-cycle phase involves minimising and managing waste.

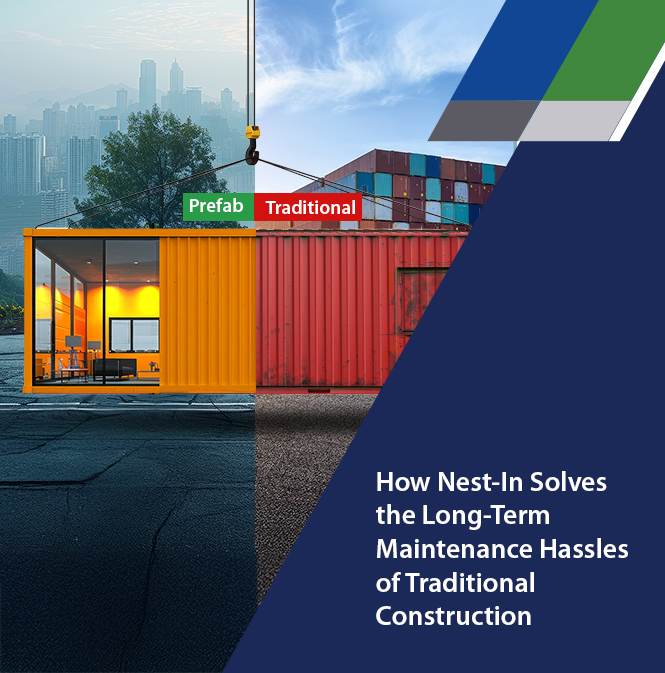

Prefabrication construction uses materials like steel that are highly recyclable, curbing energy consumption linked to new material production. At the end of a prefab building’s life cycle, the materials used will still have further value. For example, the steel frames from an LGSF structure can be reused in new projects, significantly lowering the need for additional construction and associated energy consumption. Additionally, prefab technology's controlled manufacturing environment and efficient assembly process result in LGSF components and modular structures that are precise and accurate, minimising construction waste and leading to lower energy consumption for waste disposal processes and creation of new construction material.

RCC buildings, on the other hand, use bricks and concrete, which cannot be reused for another project, or even recycled at the end of product life cycle. Additionally, the construction is heavily dependent on labour, and thus, is not always error-free and accurate, leading to a lot of construction waste being generated.

Nest-In: Your Gateway to Energy Conservation

Here are some key USPs of Nest-In’s prefab construction solutions.

Off-Site Manufacturing For Lower Energy Consumption

Nest-In's off-site manufacturing significantly reduces energy consumption during construction. The streamlined process ensures efficiency and minimal environmental impact.

Low RETV (Residential Envelope Transmittance Value)

Nest-In structures showcase a lower Residential Envelope Transmittance Value (RETV) compared to conventional buildings. This is attributed to the low U Value of Light Gauge Steel Frame (LGSF) Walls, enhancing energy efficiency.

Up to 50% Reduction In Chiller Capacity

Nest-In's innovative design results in up to a 50% reduction in chiller capacity for air-conditioned buildings, showcasing substantial energy savings in climate-controlled environments. For example, in an RCC building, an air conditioner would need to run for 8 hours on a hot day to keep the interior cool for a sustained period. Whereas, in an LGSF building, in the same conditions, the air conditioner would need to run for almost half of the duration due to efficient thermal insulation, thus saving energy.

Double-Layer Drywall With 100 mm Insulation

Implementing advanced insulation techniques, Nest-In incorporates double-layer drywall with 100 mm insulation, further fortifying its structures against energy loss and ensuring comfortable ambient temperatures inside the building

Lighter on Pocket and Environmentally Prudent

Beyond energy efficiency, Nest-In's solutions prove to be financially prudent. They are not only lighter on the pocket due to lower utility bills, but also contribute to sustainability through reduced energy consumption.

With these benefits and more, Nest-In has been a part of many residential, commercial, and industrial projects that are aimed at energy conservation and sustainability. So far, every project associated with Nest-In has observed less wastage, better reuse of construction materials, shorter construction timelines, and less labor.

The Final Word

Nest-In's prefab technology stands as a testament to the amalgamation of innovation and environmental responsibility. As it leads the charge in energy-efficient construction, Nest-In not only constructs buildings but also paves the way for a more sustainable tomorrow. With each structure it builds, Nest-In reinforces the belief that construction progress can coexist harmoniously with energy conservation, promising a future where spaces are not just functional but also environmentally conscientious.

Posted in Nest-In on Dec 04, 2023.

Contact Us

Recent Post

Climate-Resilient Construction: The Growing Demand For Weather-Ready Prefab Spaces

Stylish Modular Spaces Built for Every Terrain

How We Built Strong & Efficient Rolling Mill Main Pulpits In Ludhiana, Punjab

Climate Is Changing. Our Buildings Must Too: How Prefab Creates A Greener, Safer Future

Built for Emergencies: Why Modular Construction Is Ideal for Rapid Disaster-Relief Infrastructure

Category

- Nest-In 108

- HabiNest 65

- MobiNest 124

- Nestudio 28

- EzyNest 21

- Smart EzyNest 6

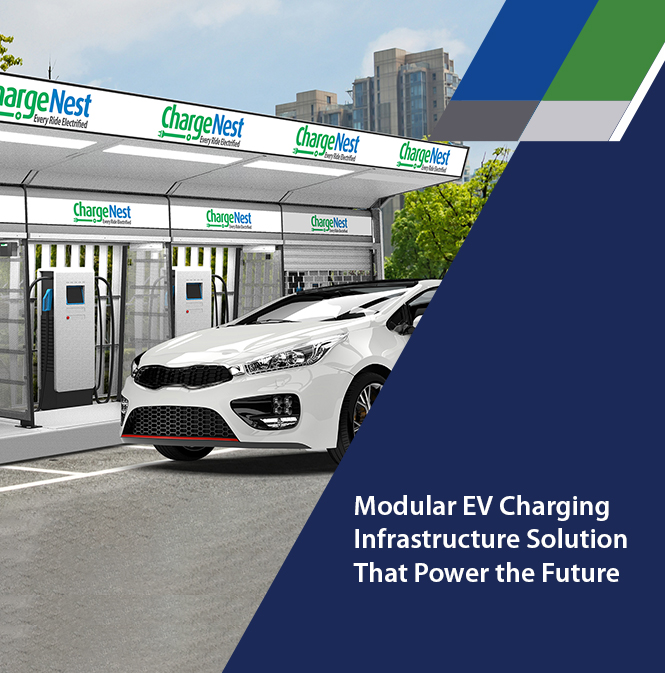

- ChargeNest 7

- Covid Offerings 4

- Brand 7

Add comment