Common Modular Building Construction Materials

Over the years, as construction technology has evolved, new techniques have been invented that are more efficient than conventional methods. One such innovative technique that has gained immense popularity is modular construction techniques which can be used to construct buildings of various sizes and complexities.

For many years, steel, concrete and wood have been used in different forms of traditional construction. Each of these materials provide specific benefits. For example, wood is lightweight yet tough, making it an ideal construction material for small and medium-sized buildings.

Steel is one of the toughest metals and a perfect material for building frameworks. Concrete too is hard and heavy, and it is one of the most preferred modular building construction materials worldwide for foundation works.

All these materials can be used in modular construction as well. Let us look at how.

Steel

Steel is one of the most popular and significant material used in modular construction. Steel is used for all kinds of modular building projects from schools to offices, hospitals, hotels and much more. (never start a sentence with and) A structure made of steel is robust enough to withstand harsh weather conditions and is best suited for difficult terrains.

HabiNest is a unique Light Gauge Steel Frame (LGSF) solution from the house of Nest-In by Tata Steel. The light gauge steel frames which are about 0.88 mm 550 mPa, 250 GSM or AZ150 Galvalume, cuts down the weight of the structure by up to 70% than the traditional RCC construction.

Steel is also an excellent construction material that is insect and termite resistant. This creates a safe space for the occupants and eliminates the hassles of termite infestation that are associated with wood-based constructions.

Steel allows a person to make the best material choice. The excellence and variety of its properties provided in a steel-based construction is vast. Let us look at some of the advantages:

- Steel is safer to use since its strength is consistent and can be designed to withstand high-impact crashes.

- Steel offers the highest strength to weight ratio of any building material.

- Steel is the material of choice because of its strength, versatility and recyclability.

- Steel buildings are designed to be easy to assemble and disassemble, ensuring big environmental savings.

- Steel structures are 70% lighter than those built from concrete.

- Most steel structures are manufactured at plants using prefabrication methods. This ensures the quality of such structures and allows for a high speed of further installation.

- Steel’s versatility allows architects to bring bold ideas to life: give any spatial shape to internal space, modify a building in the process of construction and efficiently integrate utilities.

Steel Properties for building structures

When manufacturing building structures from steel, the metal undergoes several process operations: cutting by different methods, welding, mechanical processing, bending, flattening and rolling. Steel must withstand all these operations while preserving a stable microstructure and mechanical properties.

Steel in welded structures must withstand dynamic, static and variable loads for a long period of time, often under aggressive climatic conditions with extreme temperatures. That is why there are specific requirements for structural steel in terms of strength, resistance to embrittlement, weldability, etc.

The strength properties determine how the steel is used to build a structure.

Today, steel structures are used more often than conventional concrete. Such an ‘alloy’ is strong and durable, which makes it indispensable in construction.

Contact Us

Recent Post

Strengthening Communities with Nest-In to Build a Better Tomorrow

Innovative Modular Spaces for Modern Offices and Commercial Needs

Revolutionising Industrial and Commercial Construction with Nest-In

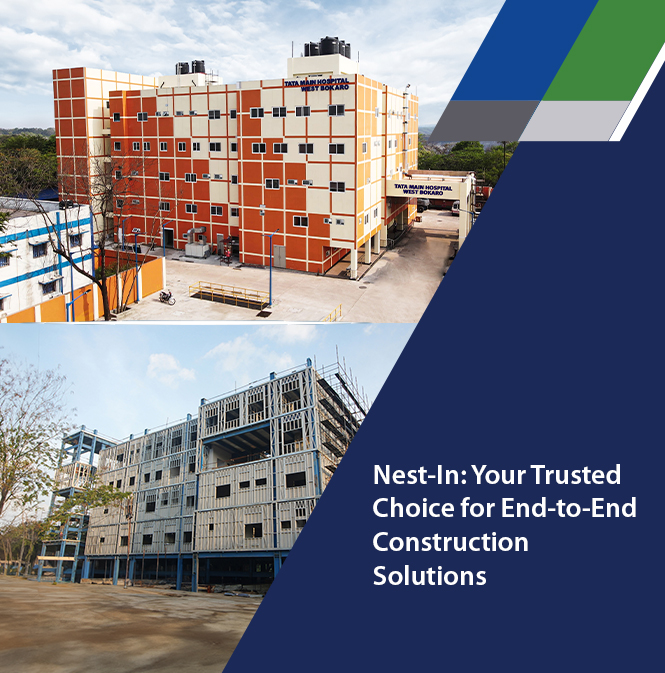

Nest-In: Your Trusted Choice for End-to-End Construction Solutions

How Nest-In Delivers Rapid, Resilient Solutions for Emergency Infrastructure

Category

- Nest-In 62

- HabiNest 59

- MobiNest 138

- Nestudio 31

- EzyNest 20

- Smart EzyNest 5

- ChargeNest 6

- Covid Offerings 4

- Brand 10

Add comment