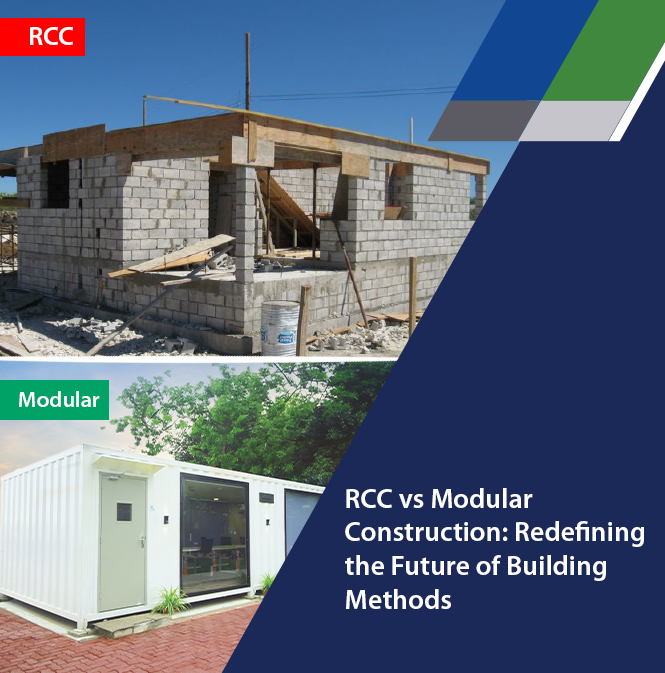

RCC vs Modular Construction: Redefining the Future of Building Methods

Over the past few decades, the construction industry in India is undergoing a revolution. Traditional building methods like Reinforced Cement Concrete (RCC) have long been the gold standard, but new, innovative approaches like modular construction are rapidly changing the game.

With growing urbanization and demands for diverse infrastructure, short project deadlines, and increasing sustainability concerns, the choice between RCC and modular construction is no longer just about preference, it’s about the benefits and sustainability of the construction project in the long run.

What Is RCC and Why Has It Been the Default Choice?

Reinforced Concrete Construction (RCC) has dominated the construction sector for decades. It is known for its durability, strength, and versatility, making it ideal for everything from skyscrapers to highways. However, it comes with challenges – on-site construction is time-consuming, the construction process is heavily dependent on skilled labor, and the project timeline is often extended due to weather-related delays. Moreover, material wastage and environmental impact remain significant concerns.

Modular Construction: A Game Changer

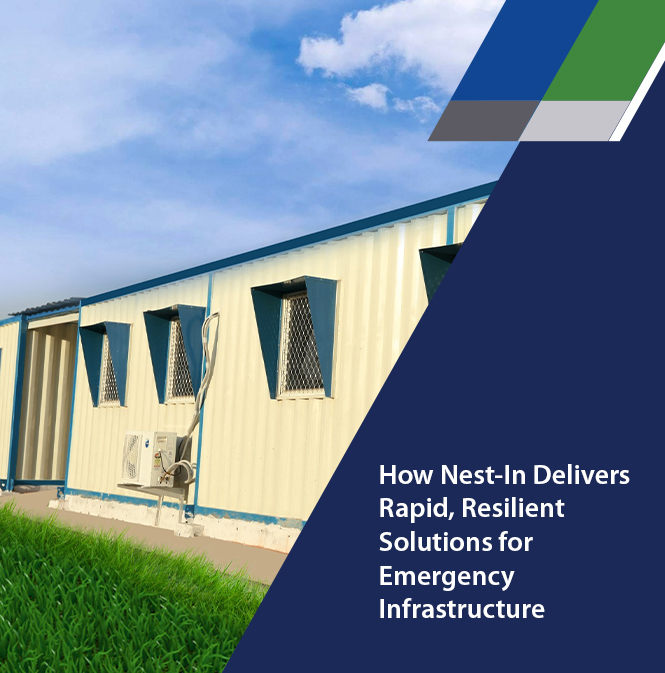

Modular construction is a smarter way of building: instead of constructing on-site, modular cabins are manufactured in a controlled factory environment, then transported and installed at the final location. This construction approach is much quicker, more efficient, and more precise than RCC construction methods.

Moreover, these modular cabins are plug-and-play in nature. Since they arrive “readymade” from the factory, they only need to be installed with electrical and plumbing connections on the site, after which they are ready to be operational. Thus, in India, modular construction solutions are becoming increasingly popular, offering faster and more sustainable alternatives to traditional methods.

RCC vs. Modular Construction: A Direct Comparison

|

Factor |

RCC Construction |

Modular Construction |

|

Nature of Construction |

On-site construction; prone to delays due to weather, labour shortages, and material availability |

Off-site construction; factory-made module transported to site for installation and electrical and plumbing connections |

|

Efficiency and Precision |

Inefficient construction due to delays; high chances of error due to human-controlled processes, large amounts of construction waste generated |

Efficient and precise construction due to factory-made nature of modules; minimal construction waste generated |

|

Sustainability |

High carbon footprint due to usage of large amounts of water for cement making and extensive use of heavy machinery; lot of waste, dust, and noise generated from on-site work |

48% less freshwater used due to dry construction; 53% less greenhouse gas impact due to offsite construction, minimal trips to and from the site, and less waste generation |

|

Quality Control |

Varies – quality depends on on-site conditions and workmanship |

Major work happens in a factory set up off-site ensures precision and uniformity |

|

Flexibility |

Permanent structures that are difficult to modify |

Highly adaptable to evolving infrastructure needs; can be expanded, reconfigured, and even relocated if the need arises |

Why India Needs to Embrace Modular Construction

The demand for rapid urban infrastructure is at an all-time high. Cities are expanding, businesses are growing, and the need for affordable, high-quality spaces for commercial, business, and public needs is increasing. Modular construction is an answer to many of these challenges. It provides a scalable and efficient solution, making it ideal for India’s evolving construction landscape.

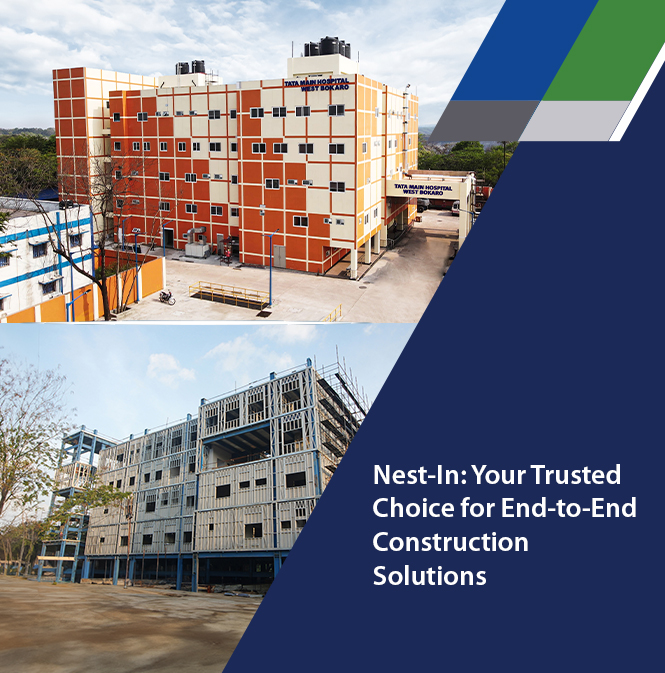

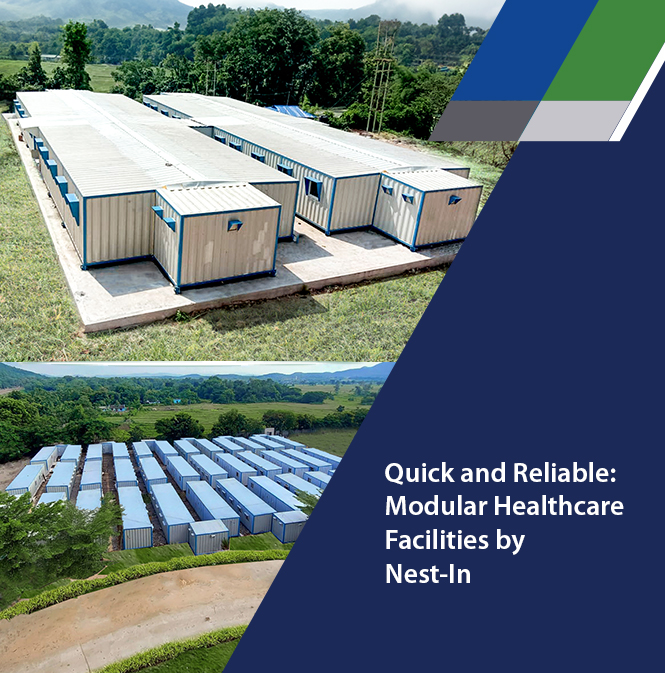

Nest-In: Pioneering Modular Construction in India

Nest-In from the house of Tata Steel is a leading provider of modular construction solutions across various states in India. Catering to a wide range of industries and applications, Nest-In's modular spaces are redefining how India builds. Our plug-and-play modular cabins are being used for offices, conference rooms, guard huts, labour and bachelor accommodation, healthcare facilities like clinics, sanitation blocks, and more. By prioritising efficiency, quality, and sustainability, Nest-In is setting new standards in the construction industry.

While RCC has been the backbone of construction for decades, the future belongs to modular construction, its advantages making it a compelling choice for businesses, governments, and agencies looking to build sustainable and high-quality infrastructure.

Visit Nest-In's website to know more about our full range of prefabricated construction solutions or to register a query.

Posted in MobiNest on Feb 25, 2025.

Contact Us

Recent Post

Prefab: The Smart Choice for Durable Infrastructure

The Process of Creating High-Quality Prefab Spaces

Prefab Spaces Combine Strength with Modern Design

Prefab for Every Industry: Meeting the Safety and Durability Needs of Businesses

Fast, Safe, and Reliable: Prefab Is the Best Choice for High-Quality Infrastructure

Category

- Nest-In 66

- HabiNest 63

- MobiNest 114

- Nestudio 28

- EzyNest 19

- Smart EzyNest 6

- ChargeNest 6

- Covid Offerings 4

- Brand 8

Add comment