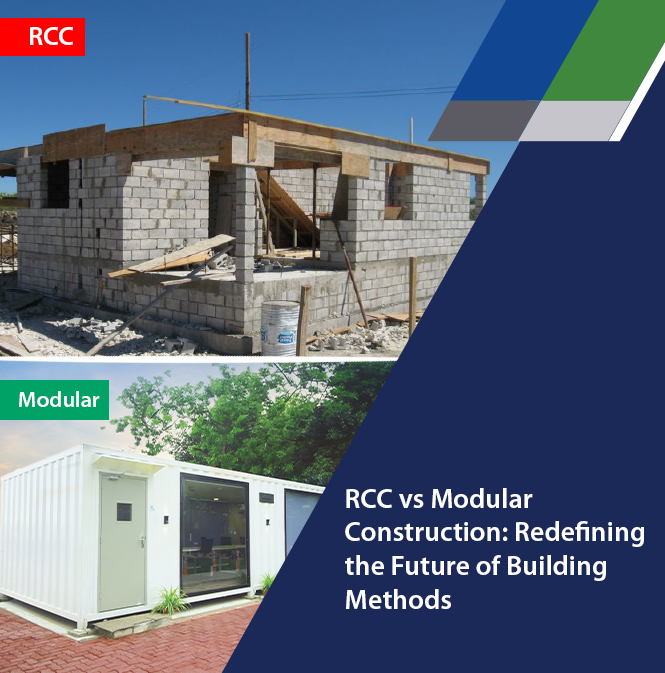

From Foundation to Finish: RCC Vs. Modular Construction

The Indian construction industry has come a long way. Over the years, technological advancement has made construction methods and techniques safe, sustainable, and cost-effective. This blog comprises a comprehensive comparison between RCC and modular construction methods, covering the merits of each method such as structural strength, the eco-friendly nature of modular construction, and the growing popularity of modular buildings in India.

Understanding Reinforced Concrete and Cement (RCC) Construction

RCC is a conventional building method that has been used for decades to build durable structures. RCC methods are mostly preferred for buildings that are supposed to have high load-bearing capacity such as flyovers, dams, and runways, to name a few. This construction method uses a mixture of concrete and cement for building different types of commercial and industrial structures. RCC is not recommended for areas with high seismic activity due to increased dead load and lower stiffness than composite structures. Additionally, RCC structures require more labour, transportation, and heavy machinery, as the construction materials are made on-site, and the construction of the structure is done on-site as well. Overall, the RCC construction process takes much longer than prefab modular construction.

Exploring Modular Construction

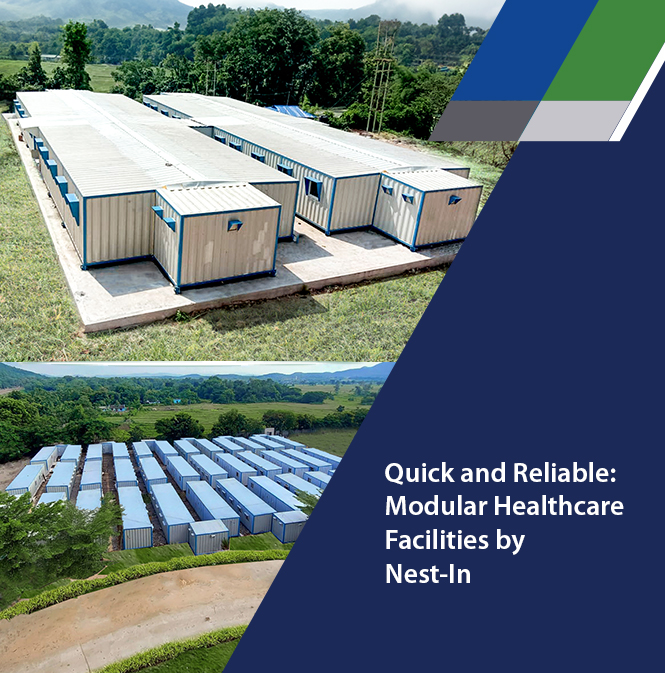

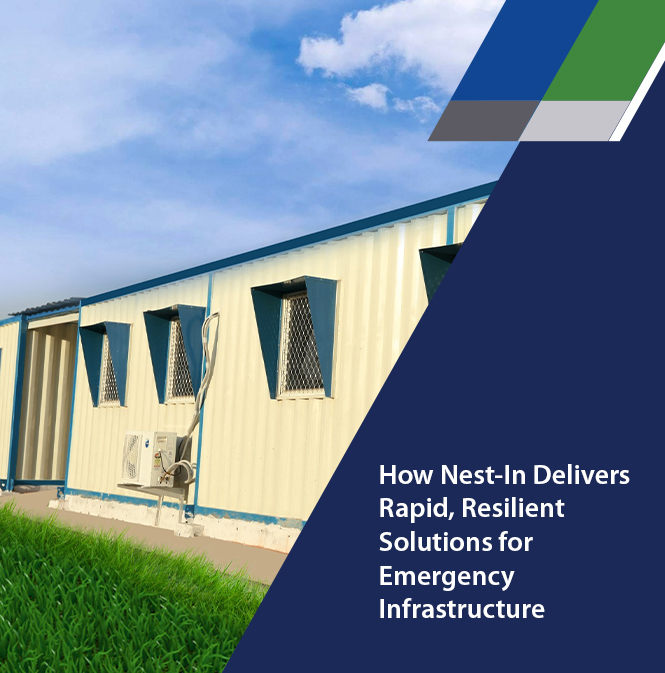

Modular construction is gaining a lot of traction due to the benefits it offers. This type of construction involves offsite manufacturing and onsite installation, which drastically decreases construction timelines Additionally, the construction materials used are eco-friendly (for example, steel is used, which is recyclable).

Benefits of modular buildings, as compared to RCC construction, include:

- 1) 2x faster construction

- 2) Reduced need of transportation and low manpower requirements, as the entire modular structure is built and assembled in a factory-controlled environment, and is transported to the site only for final installation

- 3) Materials for the modular structure are made with great precision and accuracy in the factory, which reduces the amount of construction and material waste generated

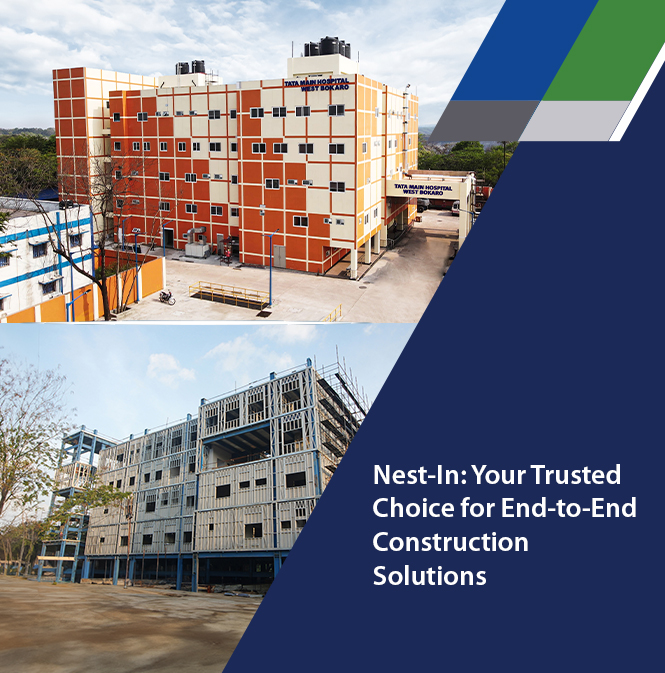

Nest-In from the house of Tata Steel, a leading prefabricated construction solutions company in India, offers a wide range of prefab construction solutions for every requirement.

Comparative Analysis Of RCC Vs. Modular Construction

|

Parameter |

RCC Construction |

Modular Construction by Tata Steel Nest-In |

|

Construction |

Has longer construction timelines and is less efficient due to heavy dependency on labour, weather conditions, and heavy machinery |

2x faster speed of construction as the entire modular structure is made in a factory-controlled environement, and transported on-site only for final installation, and electrical and plumbing connections |

|

Durability |

Known for durability and ability to withstand natural disasters |

Offer lightweight, high-strength solutions, and improved structural efficiency |

|

Sustainability and |

· Creates a lot of material and construction waste, as it is not recyclable · Uses large amounts of water for mixing and curing cement · Uses excessive energy as heavy machinery is constantly required |

· Reduced construction waste due to precision manufacturing of components and structure · Recyclable steel used as building material · Transportation only required to move finished structure to the site |

The Nest-In Solution

Modular construction in India is on the rise today. This shift in construction practices and mindset is due to the increased awareness about environmental degradation due to rapid urbanisation. Not just construction companies, but even investors, customers, and businesses are more interested in sustainable construction solutions. Over the last few years, Nest-In has helped build India’s sustainable infrastructure. It provides innovative modular building solutions like spacious and customisable plug and play cabins (MobiNest). Learn more about Nest-In’s projects and solutions on the website.

Posted in MobiNest on Jan 05, 2024.

Contact Us

Recent Post

Prefab: The Smart Choice for Durable Infrastructure

The Process of Creating High-Quality Prefab Spaces

Prefab Spaces Combine Strength with Modern Design

Prefab for Every Industry: Meeting the Safety and Durability Needs of Businesses

Fast, Safe, and Reliable: Prefab Is the Best Choice for High-Quality Infrastructure

Category

- Nest-In 66

- HabiNest 63

- MobiNest 114

- Nestudio 28

- EzyNest 19

- Smart EzyNest 6

- ChargeNest 6

- Covid Offerings 4

- Brand 8

Add comment