Innovative Practices: The Benefits of Nest-In's Prefabricated Construction

Prefab construction, often hailed as the future of the construction industry, is transforming how we approach building projects. Its efficient, sustainable, and innovative approach makes it a preferred choice for diverse infrastructure requirements. In this blog, we’ll explore the benefits of prefab construction over RCC (Reinforced Cement Concrete) construction and delve into the specific advantages that Tata Steel Nest-In offers. From speed and sustainability to various practical applications, Nest-In’s solutions stand at the forefront of this construction revolution.

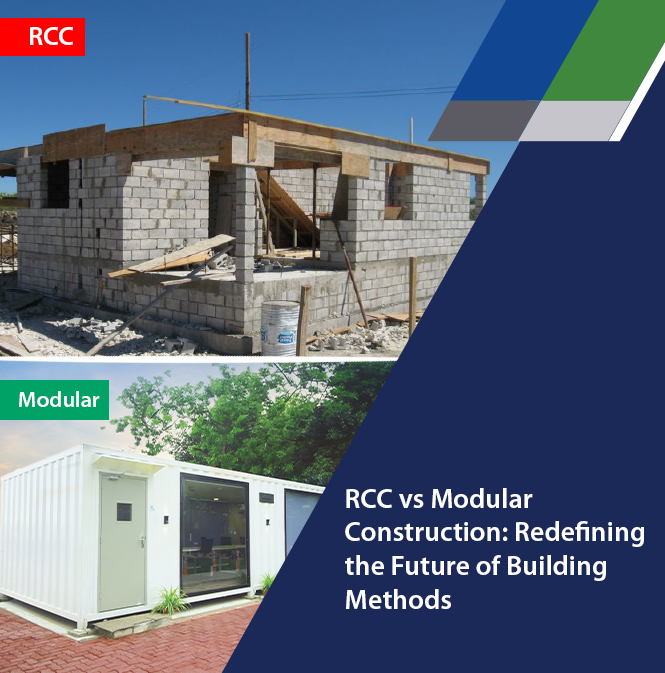

What Is Prefab Construction?

Prefab construction or prefabricated construction, involves manufacturing building components in a factory-controlled environment (off-site). These components are then transported to the project site for final assembly or installation.

The Benefits of Nest-In's Prefab Construction

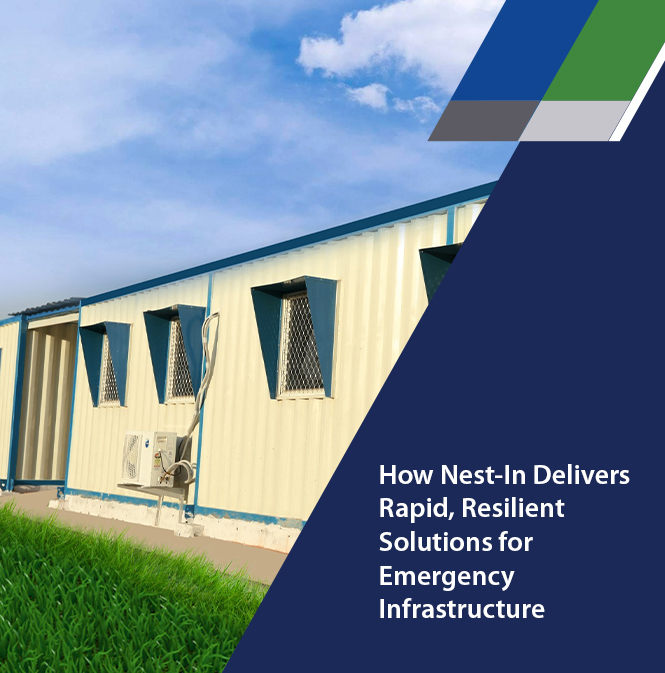

1. Accelerated Construction Timelines

Nest-In’s prefab construction process is 2x faster than traditional methods. As the prefab components are manufactured to precision in a factory, they are transported to the site only for final assembly or installation. This reduces the need for multiple trips to and from the site for raw materials, removal of waste, etc., as is common in traditional construction. Additionally, there is a reduced need for an extensive labour force.

There is also no delay in the manufacturing and construction process during adverse weather conditions, as it takes place safely indoors. This is especially beneficial for large-scale projects where time is of the essence.

2. Enhanced Quality Control

Manufacturing components in a factory setting allows for stringent quality control. Every piece is produced with consistent precision, ensuring high quality standards that are often difficult to achieve with on-site construction. This consistency leads to better durability and fewer repairs over the structure’s lifespan.

3. Sustainability and Reduced Environmental Impact

Prefab construction is inherently more sustainable than traditional methods. The factory environment allows for better management of resources, reduction of waste, and enables the recycling of the steel structures. For example, Nest-In's construction processes use 48% less freshwater than traditional methods. This is because cement is only used in the foundation, while the rest of the structure is dry. Thus, only a small volume of water is needed to dry and cure the cement. Additionally, 65% less material resources are used due to the optimised use of resources and raw materials during construction.

Furthermore, prefab buildings have a smaller carbon footprint, as the efficiency of the construction process results in lower overall emissions. According to the World Green Building Council, prefab methods can reduce construction waste by up to 90%. Nest-In's prefab construction has 53% lower greenhouse gas impact than traditional methods due to the factors mentioned, as well as the reduced usage of transportation infrastructure, heavy machinery, and an extensive labour force.

4. Safety First Approach

Safety is paramount in all of Nest-In’s projects. Our solutions are designed and manufactured to meet the highest safety standards, ensuring a secure construction process and a robust product. The off-site production reduces the risks associated with on-site construction, further enhancing safety. All our experts, both on-site and off-site, are required to wear high-quality PPE (personal protective equipment) like hard hats, gloves, safety goggles, and high-visibility vests. Additionally, as we need a smaller workforce on-site as compared to RCC construction processes, there are stricter checks on the implementation of safety protocols.

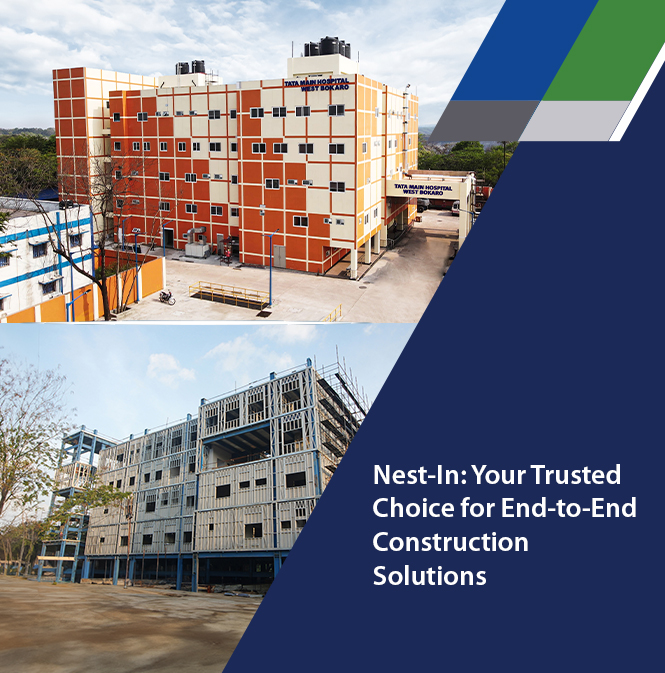

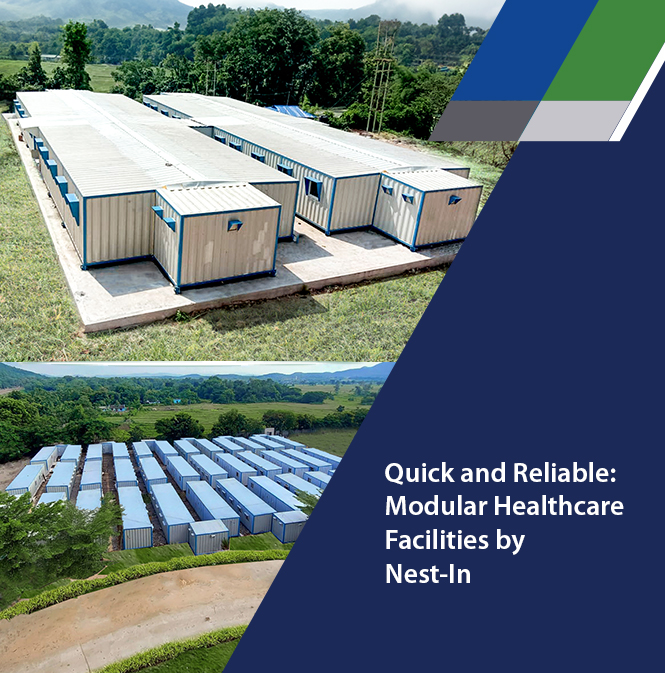

5. Versatile Applications Across Industries

Nest-In’s range of prefab solutions is incredibly versatile, catering to projects for businesses, governments, and individuals, and ranging from modular offices to multistorey buildings and EV charging stations, from home rooftop extensions to premium villas, from plug-and-play toilet units to smart, automated sanitation solutions. Nest-In provides complete turnkey solutions that are tailored to the customer’s need.

Building a Sustainable Future with Nest-In

Prefab construction represents a leap forward in building technology, offering unmatched benefits in speed, energy savings, quality, and sustainability. Nest-In exemplifies these advantages, providing cutting-edge prefab construction solutions that are transforming the industry. By choosing Nest-In, customers can ensure their projects are completed with the highest standards of efficiency and sustainability, leading to successful outcomes every time. For more detailed insights into Nest-In’s prefab solutions and their applications, visit the website.

Posted in Nest-In on Aug 01, 2024.

Contact Us

Recent Post

Prefab Spaces Combine Strength with Modern Design

Prefab for Every Industry: Meeting the Safety and Durability Needs of Businesses

Fast, Safe, and Reliable: Prefab Is the Best Choice for High-Quality Infrastructure

Building Sustainable and Safe Infrastructure with Tata Steel Nest-In

Nest-In Prefab Construction Delivers Speed Without Compromising Quality

Category

- Nest-In 65

- HabiNest 62

- MobiNest 114

- Nestudio 28

- EzyNest 19

- Smart EzyNest 6

- ChargeNest 6

- Covid Offerings 4

- Brand 8

Add comment